Having All Your Equipment Information and Maintenance Records in Excel? You Are in Trouble

Chang

In many factory environments, Excel is often the go-to tool for documenting essential data such as machine records, maintenance activities, and inventory levels. It's flexible, allowing users to customize tables and formats that best suit their immediate needs. For small-scale operations, Excel can indeed be a useful, versatile tool.

However, as your operations scale, relying on Excel quickly becomes problematic. Here's why:

Why Excel Falls Short for Complex Maintenance Management

Excel, fundamentally, is table-based software. It works well when each row represents an individual piece of equipment or a single maintenance record. But what happens when relationships become more complex, involving one-to-many, many-to-one, or even many-to-many interactions?

While Excel pivot tables can handle basic summaries and some relationships, handling complex relational data quickly becomes cumbersome and error-prone. Consider a scenario where multiple pieces of equipment use shared inventory items, or multiple work orders require intricate tracking. Such scenarios typically require multiple interconnected sheets or pivot tables, demanding advanced Excel skills, significant time investments, and are inherently fragile—prone to errors with the slightest incorrect entry.

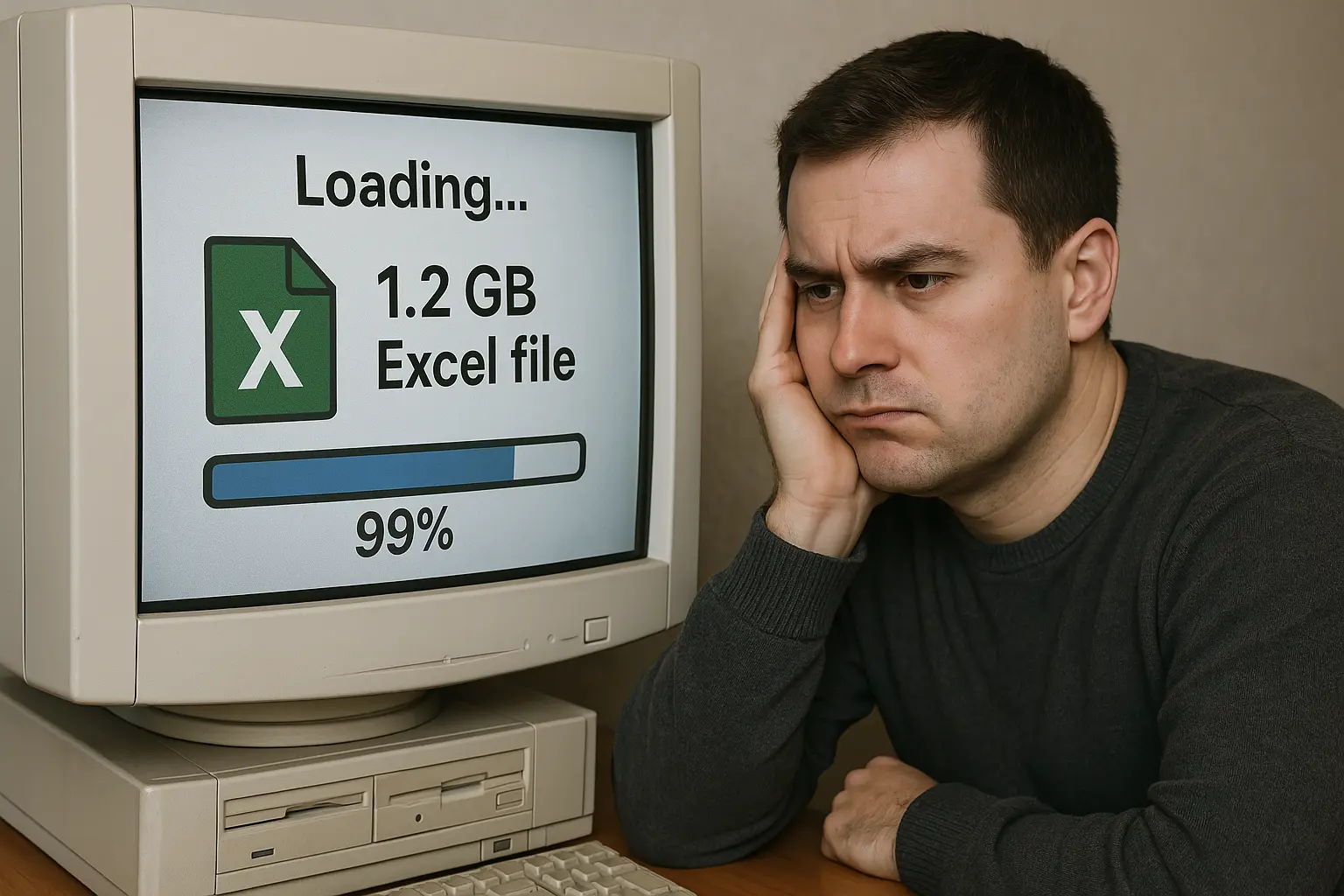

Moreover, large-scale operations might find themselves juggling Excel files reaching several megabytes or even gigabytes, significantly slowing down data loading and processing. This critical bottleneck can disrupt your entire operational flow, leading to delays, miscommunication, and costly mistakes.

The Benefits of Using CMMS Maintenance Software

This is exactly where CMMS maintenance software (Computerized Maintenance Management Software) comes into play. Unlike Excel, CMMS maintenance software is specifically designed to manage the complex data relationships inherent in maintenance operations. It prevents erroneous data entry by providing structured forms and validation, drastically reducing human errors.

A CMMS maintenance software system operates on a robust, scalable database, allowing effortless management of thousands of records without performance degradation. It simplifies complex calculations, automates logic processing, and produces instant reports—streamlining data handling for factory management.

With CMMS maintenance software like Cerev CMMS, you can automate data handling, from data entry through report generation. Users input data through user-friendly interfaces, and the CMMS system generates accurate, real-time PDF reports for secure storage, analysis, and regulatory compliance. This seamless automation and improved accuracy represent significant efficiency gains, particularly crucial for large-scale manufacturing environments.

Make the Switch from Excel to CMMS Maintenance Software Today

If your current operation relies heavily on Excel, you're operating a ticking time bomb. Don't let outdated systems hinder your growth and operational efficiency.

Cerev CMMS provides the solution you need. Consult with our CMMS maintenance software experts today, and discover how to transform your maintenance operations to a streamlined, automated, and reliable management system designed for scale.

Ready to optimize your maintenance operations?

Get in touch with our team to discuss how Cerev CMMS can help streamline your maintenance workflow and reduce costs.